Pelican Protector™ cases have evolved over the years to accommodate the needs of electronic engineers and their OEM projects. Injection molding provides a reliable, durable, ready-to-ship enclosure with consistent dimensions. The co-polymer material can be machined and drilled, and also files and sands well.

These properties make the Pelican Protector™ Case well suited for customization such as mounting bulkhead connectors, while maintaining a clean, professional appearance. Attaching equipment to the interior is equally simple by use of typical fasteners and mounting hardware. The hardware can be made water-tight by use of small o-rings, rubber washers or silicone.

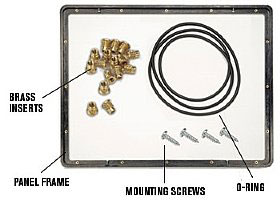

PANEL FRAME INSERTS

Panel frames allow the simple attachment of an interface panel flush with the rim of the case. The depth of the lid allows switches, buttons, connectors and ports to stand up from the panel face.

We provide the mounting bracket, fasteners and o-ring which install beneath the panel and fit against tops molded inside the case walls. A polymer o-ring seals the panel so the case remains watertight, even with the lid open. Pre-drilled holes and stainless steel screws make fabricating a custom case faster, stronger and more accurate.

panel frame inserts

The interior of the lid is also commonly used to attach accessories such as a wiring race, device holster or Pelican’s optional lid organizer sets. Select larger cases offer mounting bosses inside the lid for use with screw fasteners.

Custom Case Company

Custom Case Company HPRC

HPRC NANUK

NANUK TrekPak

TrekPak Pelican Protector

Pelican Protector Pelican Air

Pelican Air Pelican Cargo Cases

Pelican Cargo Cases Pelican Storm

Pelican Storm Pelican Travel

Pelican Travel Pelican Personal Utility Cases

Pelican Personal Utility Cases Pelican Elite Coolers

Pelican Elite Coolers Pelican ProGear

Pelican ProGear Pelican Vault

Pelican Vault Pelican Lights

Pelican Lights Pelican Hardigg ISP Cases

Pelican Hardigg ISP Cases Pelican Hardigg Rack Cases

Pelican Hardigg Rack Cases Pelican Hardigg Single Lid Cases

Pelican Hardigg Single Lid Cases Pelican Mobile Military

Pelican Mobile Military SKB

SKB Underwater Kinetics

Underwater Kinetics Invoices

Invoices